Bans in the Disposable Plastics Directive: Only airpop / EPS to-go packaging for immediate consumption affected

Bad Homburg, 4 June 2019 – A misleading press release from the EU Commission dated 21 May 2019 concerning the EU Single-Use Plastics Directive and an article in the newspaper Süddeutsche Zeitung dated 22 May 2019 have resulted in a number of misconceptions in the public perception that wrongly damage the image of expanded polystyrene (EPS – airpop / polystyrene) as an established and efficient packaging plastic.

This has prompted IK Industrievereinigung Kunststoffverpackungen (German Association for Plastic Packaging and Films) to present a new fact check on EPS packages.

Prohibitions in the Single-Use Plastics Directive: Only takeway containers for immediate food consumption are affected

EPS fish crates convince with their special protective properties and good recyclability.

The European Single-Use Plastics Directive does not constitute a general ban on EPS packages, as the headline in the Süddeutsche Zeitung of 22 May 2019 suggests. As the name says, only single-use packages are affected – namely special takeway containers made from EPS.

The prerequisite for prohibition is that the package is intended to contain protected food requiring no further preparation for immediate consumption. All other airpop packages are explicitly not affected by this EU Directive.

The takeway EPS packages mentioned in the Directive represent just one of many fields of application for EPS packaging. The majority of it is used for packaging for electrical appliances/white goods etc., as well as for example in transport containers for sensitive medical/pharmaceutical products requiring thermal insulation, i.e. that need to be kept cool or warm.

EPS packaging is also used in the food industry to protect delicate and temperature-sensitive food such as fresh fish. It would be difficult to replace EPS in all these applications owing to its favourable properties. None of the alternative materials offers a better ecological profile for the packaging and transportation of these goods (source EUMEPS/ FWC 2018 LCA Fish Box).

Airpop can be recycled very well and has been recycled for some time

EPS is a recycling material that can be recycled very well, as it consists exclusively of polystyrene. Almost 50% of the material is successfully recycled in Germany (source: Conversio Study 2017 on EPS waste flows). However, the explanations in the article in the Süddeutsche Zeitung create the impression that EPS is not recycled and that it also interferes with the recycling flows of other materials.

Airpop has been materially recycled by specialist businesses in Germany for many years, i.e. melted down and processed before re-entering the production cycle and being transformed into new products (source: Conversio Study 2017 on EPS waste flows). These businesses collaborate with the disposal companies of furniture and electronics retailers. Consumers in Germany can take their airpop packaging (e.g. used to package a washing machine) to collection points or household waste recycling centres for reprocessing.

This ensures that they are recycled. A total of 80% of all airpop packaging is collected outside the “yellow sack” collection scheme. A small quantity of used EPS packaging is disposed of in many municipalities via the “yellow sack/yellow bin” scheme. So far, these small quantities have not been extracted by sorting plants from the waste flow of the “yellow sack” scheme and returned to material recycling for economic reasons. The industry is working on new recycling solutions in this area as well.

EPS packaging for washing machines is collected and recycled.

Furthermore, the EPS contained in the takeaway packages at the centre of the debate is processed in a special way and does not lead to small granulate particles being produced as described in the Süddeutsche Zeitung article.

EPS packages are made up of 98% air:

Airpop packages contain only 2 per cent polystyrene. It is an efficient way of using the resource petroleum for packaging purposes.

Biodegradability of airpop

Like most high-quality plastics, EPS/polystyrene is not biodegradable. As a packaging material, airpop offers stability, high compressive strength and is also waterproof, shock-resistant and provides thermal insulation as the relative applications require. In contrast, biodegradable plastics were developed for applications involving biological waste collection and e.g. agricultural films.

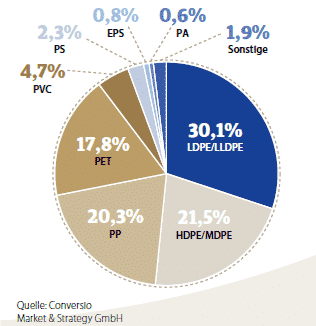

Packaging production according to types of plastic used (2017): EPS packaging is a highly specialized niche application.

EPS compared to other materials

EPS has a poor reputation for no good reason. The material is resource-friendly and provides effective protection. Other materials are rarely an ecological alternative. Less raw materials, chemical and water are required in the production of EPS than for other packaging materials, e.g. a third less water is used in the production of airpop compared with laminated cartonboard, and it is up to eight times lighter (source: EUMEPS/ FWC 2018 LCA Fish Box). This makes EPS a very sustainable packaging material.

EPS share of German packaging production

The material possesses very specific properties, while accounting for less than one per cent of packaging production in Germany.

Analyses have shown that polystyrene contributes less than one per cent of the plastics found on beaches. The fact that an analysis of the most common types of waste in the category of plastics/polystyrene shows that EPS accounts for 31% of the total is misleading. (Source: JRC Technical reports, TOP Marine Beach Litter Items in Europe)

Polystyrene is a plastic.

For reasons that the industry does not understand, (expanded) polystyrene is often reported as a dedicated category besides plastic. The analysis of the most common types of waste found on beaches covered by the Single-Use Plastics Directive also makes this misleading distinction. This contributes to the confusion and false interpretations, and is incorrect.

Our experts will be happy to provide you with further information. For more information, visit: www.airpop.de

The following the integrated video give a good overview of the application possibilities of Styrofoam and airpop.