In addition to the recyclability of packaging, one of the most important topics in the discussion about the circular economy is the question of how and up to what quantity the proportion of recyclates in plastic packaging can be increased.

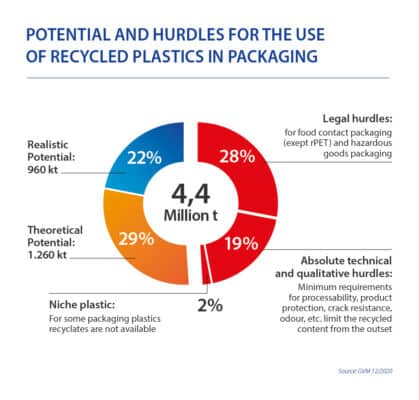

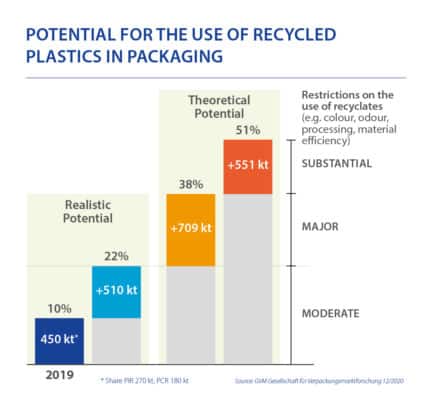

The German Plastic Packaging Association IK has asked GVM (Society for Packaging Market Research) to analyse the overall potential for the use of recycled material in plastic packaging: According to their study the use of recycled plastic in packaging in Germany could be increased from 475 today to about 960 thousand tonnes per year, which corresponds to about 22 percent of the total production volume. However, the technical application potential of recyclates varies greatly depending on the type of packaging: while some packaging, such as PET beverage bottles, can already be made entirely from recyclates today, there are high legal and technical barriers for other types of packaging. The use of one million tonnes of recycled plastic by 2025 is already the declared goal of the German plastic packaging industry.

“The manufacturers of plastic packaging in Germany are focusing on innovations and investments in the entire value chain in order to use more recyclate in their products,” says IK Managing Director Dr Isabell Schmidt, explaining the industry’s recycling strategy. The race to catch up has already begun: Between 2017 and 2019, the demand for recyclates increased by more than 18 per cent, while at the same time the consumption of virgin plastics declined. “This decoupling shows the enormous interest of the packaging industry in the use of recyclates,” says Schmidt.

Recyclates save CO2 emissions

But using recyclates at any price is neither sensible nor possible. Many types of packaging place the highest demands on the quality of the raw materials, especially food packaging, which accounts for 44% of the market. At the moment, however, the quantities of suitable recyclates on the market are limited. The reason for this is that plastic recycling in the past was driven by meeting legal recycling quotas, not by the raw material needs of the packaging industry. Therefore, there has been little investment in the production of high-purity grades for food contact in recent decades. Currently, a large part of the recyclates is used in other industries, for example in the production of building products. After all: here, too, recyclates replace the consumption of virgin plastics and save CO2 emissions.

But the framework conditions are currently changing. “By 2045 at the latest, the year in which Germany wants to be climate-neutral, plastics must be produced entirely from recyclates and other renewable raw materials,” Schmidt explains the industry’s vision for the future. The change away from fossil raw materials is radical. It requires the industry to invest billions of euros in design-for-recycling and the expansion of high-quality sorting and recycling processes.

Before recycling comes collection & sorting

Another challenge is separate collection: currently, a large part of plastic waste still ends up in residual waste or in commercial waste similar to residual waste, where it is heavily mixed and polluted. Separating it is uneconomical. “But recycling works best when plastic waste is collected separately – we see this best in the deposit collection of PET beverage bottles. Here, recyclates are produced that even meet the strict legal requirements for food contact. In order to meet the future raw material needs of the plastics processing industry, politicians must work towards significantly improving separate collection throughout Europe and completely banning the landfilling of plastic waste,” Schmidt demands.

You can find examples of successful use of recycled materials in plastic packaging and further information on the plastics circular economy here in this newsroom.